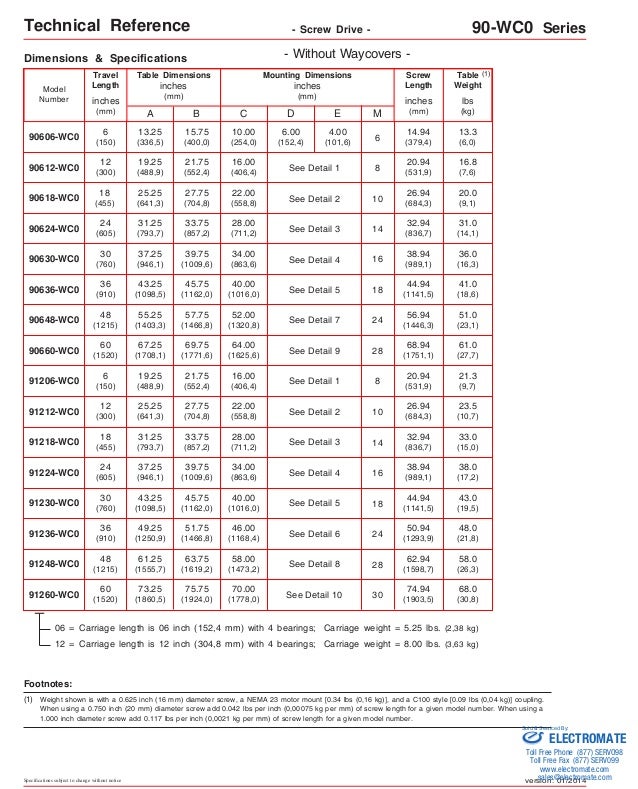

Metric Woodruff Key Slot Dimensions

Minimum order 3 pieces per size. To determine the Tool Number, add the decimal size to the tool number in the chart below. Example: 28100SPT-114 is for a 3/16' Diameter x.114' Cutter Width. Longer neck tools are quoted on request. Delivery is 7-10 days for uncoated tools. Home / Spotting Drills / NC Spotting Drills / Type I / Metric. 90deg Angle 130deg Angle Primary Sidebar. Search Products. Search ARCH Cutting Tools. Contact ARCH Cutting Tools – Centralized Distribution Center. Email: archctsales@archgp.com. Phone: (888) 390-2050.

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint.[1][2] A keyed joint may allow relative axial movement between the parts.

Commonly keyed components include gears, pulleys, couplings, and washer

Types[edit]

There are five main types of keys: sunk, saddle, tangent, round, and spline.

Sunk key[edit]

Types of sunk keys: rectangular, square, parallel sunk, gib-head, feather, and Woodruff.

Parallel keys[edit]

Parallel keys are the most widely used. They have a square or rectangular cross-section. Square keys are used for smaller shafts and rectangular faced keys are used for shaft diameters over 6.5 in (170 mm) or when the wall thickness of the mating hub is an issue. Set screws often accompany parallel keys to lock the mating parts into place.[1] The keyway is a longitudinal slot in both the shaft and mating part.

The keyseat in a shaft for a parallel key

A sprocket with an internal parallel keyway

Cross-section of a parallel keyed joint

- W = d/4[clarification needed]

- H = 2d/3[clarification needed]

where

- W is the key width

- H is the key height

- d is the shaft diameter

Woodruff keys [edit]

Woodruff keys are semicircular, fitting partly into A*B circular segment keyway with the remainder fitting into a longitudinal slot keyway in the mating part. The circular segment can be cut directly by plunge cutting with a circular Woodruff cutter without any reliefs. The main advantage of the Woodruff key is the elimination of milling near shaft shoulders, where stress concentrations,[2] and concentricity would be affected.[1] The latter is particularly important for high speed operation. The more exact fit of the key and keyway also reduces play, and stress concentrations in, and improves the reliability of the key. An additional advantage is a stuck key can be removed from a shaft with a hammer blow, the circular profile will push the key out of the slot, as opposed to a standard key which will need to be pushed axially, or pulled out of its slot. Common applications include machine tools, automotive applications, snowblowers and marinepropellers.

This type of key was developed by W.N. Woodruff of Connecticut. In 1888, he was awarded the John Scott Medal by the Franklin Institute for his invention.[3]

A Woodruff key installed

A Woodruff key and keyway

Gear G is positively located on shaft S by Woodruff key N

Tapered keys[edit]

The tapered key is tapered only on the side that engages the hub. The keyway in the hub has a taper that matches that of the tapered key. Some taper keys have a gib, or tab, for easy removal during disassembly. The purpose of the taper is to secure the key itself, as well as, to firmly engage the shaft to the hub without the need for a set screw. The problem with taper keys is that they can cause the center of the shaft rotation to be slightly off of the mating part.[1] It is different from a tapered shaft lock in that tapered keys have a matching taper on the keyway, while tapered shaft locks do not.

Others[edit]

A Scotch key or Dutch key features a circular keyway hole (instead of rectangular), produced by drilling axially into the assembled hub and shaft, with a metal dowel pin serving as the key. If the hole and key are tapered, the key is referred to as a Dutch pin, which is driven in and optionally finished by cutting or grinding flush with the end of the shaft. If a straight Dutch keyway hole is optionally tapped with a thread, then an ordinary screw serves as the threaded Dutch key.

Spring pins are an alternative Dutch key component, instead of solid dowel pins. A spring pin is self-fastening and does not work loose under vibration. Hollow spring pins provide a weaker shear strength than a solid dowel pin, and the strength may be varied by varying the wall thickness. This limited shear strength specification is designed to sustain normal operation, but then give way in the event of excessive shaft torque, thus protecting the rest of the machine from damage.

Introducing an additional bushing component between hub and shaft improves the performance and convenience of keyed joints. Taper-Lock bushings are keyed hub fittings which provide three threaded Dutch keyways and two setscrews as Dutch keys, in addition to the rectangular keyway. The Dutch keyways are threaded only on the alternate hub side or shaft side, with a thread clearance hole form on the opposite side. By simply driving setscrews into selected holes, the hub mechanism conveniently operates to rigidly lock or definitely release from the shaft, without hammering or hub-pulling. Quick-disconnect (QD) bushings work similarly, but place a circular pattern of three unthreaded and three fully threaded holes further out from the shaft axis on a bushing flange, instead of across the bushing-to-hub interface.

A Hirth joint is similar to a spline joint but with the teeth on the end of the shaft instead of on the surface.

Saddle keys[edit]

These types of keys are generally attached to the driving member (e.g. shafts). These types of keys have less strength as compared with the sunk keys. These are rarely used keys, to transmit lower power to the driven members (e.g. couplings)

Tangent keys[edit]

Tangent keys are used in high-torque heavy-duty applications. The keyway is similar to a parallel key, except it extends tangentially out of the external shaft into the internal shaft. What would have been the side of each keyway forms heels against which the key sits, and transfers force compressively. This latter point means that for reversible motion of the shaft, another key along a tangent outwards in the opposing direction is needed. Typically this will be offset by 90° or 180° on the shaft. The key may be wedge, rectangular, or square shaped, but particularly rectangular double-taper keys are used.

Spline key[edit]

This type of key uses multiple keyways in the hub to transmit high power.

Keyseating[edit]

Keyseating is the creation of the slots in the mating items. Keyseating can be done on a variety of different machines including a broach, a keyseater, wire-cut EDM, a shaper or vertical slotting machine, either a vertical or horizontal mill, or with a chisel and file.

Keyway cutters

Special cutters

Slotting tools

Different slotting tools

Broaching[edit]

Broaching is primarily used to cut square cornered internal keyways. The specific broach, bushing and guide are used for each given keyway cross-section, which makes this process more expensive than most of the alternatives. However, it can produce the most accurate keyway out of all the processes. There are three main steps in broaching a keyway: First, the workpiece is set on the arbor press and the bushing is placed in the opening of the workpiece. Next, the broach is inserted and pushed through, cutting the keyway. Finally, shims are placed between the bushing and the broach to achieve the correct depth necessary for the key.[4]

Keyseater[edit]

Keyseaters, also known as keyseating machines and keyway cutters, are specialized machines designed to cut keyways. They are very similar to vertical shapers; the difference is that the cutting tool on a keyseater enters the workpiece from the bottom and cuts on the down-stroke, while the tool on a shaper enters the workpiece from the top and cuts downward. Another difference is a keyseater has a guiding system above the workpiece to minimize deflection, which results in a closer tolerance cut. The process starts by clamping the workpiece to the table with a fixture or vise. The workpiece is properly located and then the reciprocating arm is started. Some models have a stationary table so the cutter is fed horizontally into the workpiece, while others have a movable table that feeds the workpiece into a fixed cutter. These machines can cut other straight sided features other than keyways (see the picture). They can also produce blind slots, which are slots that do not extend through the whole workpiece.[5][6]

Wire-cut electrical-discharge machining (EDM)[edit]

Wire-cut electrical-discharge machining (EDM) is primarily used for small production lot sizes where either extreme precision is required or other cutting technologies are not readily available. Wire-cut EDM cuts keyways by eroding material away from the workpiece through a series of rapid electric current discharges between a spooling wire and the workpiece through a dielectric liquid. Computer numerical control (CNC) wire-cut EDM machines allow for a wide variety selection of keyways to be cut, inclusive of multiple keyways on the same hub. The main limitations of CNC wire-cut EDM is the time it takes to cut a keyway as well as the size of parts a given wire-cut EDM machine can accommodate.[7]

Shaping or slotting[edit]

Shaping or slotting is largely used for cutting keyways that do not extend through the full length of the part. Like keyseating, shaping uses a single-point cutting tool for cutting, however, shapers are not guided through the cut on a fixed post. As such, shaper cuts are generally more susceptible to deflection than keyseater cuts.[7]

Milling[edit]

Parallel, tapered, and Woodruff keyways can be produced on a milling machine. End mills or slotting cutters are used for parallel and tapered keyways, while a Woodruff cutter is used for Woodruff keyways.[8]

For internal keyways that are not too long, the keyways can be milled if a radius is acceptable.

Chiseling[edit]

One of the earliest forms of keyseating was done by chiseling. The keyway is roughed out using a chisel and then filed to size; the key is tried frequently to avoid over filing. This technique is long, tedious, and rarely used anymore.[9]

Keyed joints[edit]

A shear key is a feature intended to fail and avoid further damage should the machinery be accidentally operated in excess of its design limits. Shear keys may be any of the designs described above, but are made from a weaker material than the shaft. The shear key is easily and inexpensively replaced, and avoids more serious damage to the mechanism that would be costly or difficult to repair. For example, a steel shaft and pulley may employ a brass key. When excessive torque is applied to the joint, the steel edges shear the brass key into two pieces, leaving the pulley spinning loosely on the shaft and relieving the rest of the machine from possible damage.

Two parallel keys can be used if the shaft connection requires a higher torque rating.[1]

Improperly machined keyways that had cutter deflection or drifting occur, may not be strong enough for the required application.[10]

See also[edit]

References[edit]

- ^ abcdKeys and Keyways(PDF), archived from the original(PDF) on 2010-03-19, retrieved 2010-03-19.

- ^Shigley, Joseph; Mischke, Charles (1989), Mechanical Engineering Design (5 ed.), McGraw-Hill, ISBN0-07-331657-1.

- ^Garfield, Eugene (2007). 'The John Scott Award Recipients from 1826 - present'. Retrieved 2007-08-23.

- ^Krar, S. F. (1983). Machine tool operations. (pp. 84–85). New York: Gregg Division McGraw-Hill.

- ^Keyseating, retrieved 2010-01-30.

- ^Wick, C. H. (1964). Versatility of keyseating. Machinery (NY), 70(8), 138-140.

- ^ abCutting Keyways - Broaching, Keyseating, Wire-Cut EDM, Shaping, & Milling, retrieved 2014-12-03.

- ^Kibbe, R. R. (1995). Machine tool practices. (5th ed. ed., p. 572). Englewood Cliffs, New Jersey: Prentice-Hall, Inc.

- ^Leonard 1908, p. 40 harvnb error: no target: CITEREFLeonard1908 (help).

- ^Romig, J. V. (1926). The Popular Science Monthly. The Popular Science Monthly., 110(5), 72, 124.

Bibliography[edit]

- Leonard, William Samuel (1919). Machine-shop Tools and Methods (Revised 7th ed.). New York: John Wiley & Sons. pp. 39–42. OCLC848146647. Retrieved 30 April 2019.

External links[edit]

| Wikimedia Commons has media related to Keys and keyways. |

- Key joint article from the 1979 Great Soviet Encyclopedia

Machine Keystock Express’ goal is to offer lower prices on machine key stock and ready-to-use machine key sizes than other sellers.

All listed items are in stock and we ship our machine keys from the USA quickly! We ship only to the USA and Canada.

This website’s online store sells small quantities to retail customers of ready-to-ship machine keys that are in stock. For large quantity wholesale machine key orders or special order machine keys you need us to manufacture quickly, please visit our wholesale website.

Machine Keystock Express manufactures machine keys of the highest quality that meet ISO 9001 certifications. Our machine keys are manufactured with SS304 stainless steel and SC45 carbon steel and alloy steel in many sizes.

If you normally buy machine key stock to make your own machine keys, you may find it cheaper to buy our ready-made keys in the sizes you need, which can be less costly than your labor needed to work with key stock.

We manufacture several kinds of machine keys in many sizes:

- Woodruff keys are half-circle shapes, with radius or flat bottoms. DIN-6888.

- Parallel keys are rectangular shapes with ends that are square (DIN-6885-B), round (DIN-6885-A), or both (DIN-6885-AB). We have in stock ready-to-use keys in inch and metric sizes

- Key stock is very long so you can cut it into whatever size machine keys you need. We have ready-to-ship key stock in inch and metric sizes.

Need Wholesale Quantities?

We have the lowest prices and can manufacture

any kind of precision machine keys or parts you need.

Visit our wholesale site and we’ll provide a price quote

What Are Machine Keys,

Also Known as Shaft Keys?

Machine keys are used in power transmission to transmit torque between a shaft and a shaft mounted component such as a gear, pulley, or coupling. Both the shaft and the component must be machined with a keyway of the appropriate size and style for the key to be used.

Machine keys are sometimes called shaft keys, or sunk keys, and are available in a variety of types and include Parallel Keys, Flat Keys, Woodruff Keys, Square Keys, Rectangular Keys, Plain Taper Keys, Gib-Head Taper Keys, Perpendicular Pins and the Feather Key.

Machine Keys have a wide range of applications in our daily lives. Machine Keys hold machinery parts in place or align components. Machine Keys are used in power transmissions, motors, speed reducers, variators, automobiles, motorcycles, and industrial machines.

Each machine key has few attributes such as width, height, length, finish, and tolerance. It is important to understand the tolerance attribute. There are two type of tolerance. An oversize tolerance machine key provides a slightly tighter fit and an undersize tolerance machine key provides a slightly looser fit. Tolerance is specified in standards such as DIN6885 and JIS B 1301. Machine keys with metric (mm) measurement are almost always made as close tolerance undersized, whereas machine keys with imperial measurement (inch) tend to be made in both oversize and undersize tolerance sizes.

Sometimes the term machine key and keystock are used interchangeably. However, the term keystock refers to a “stock” of material that is 300mm, 1 foot or longer in length, and from which machine keys are made. Machine key refers to a finished product that is installation ready. Keystock is often used in post market repairs or small production. Keystock and machine keys are made from material such as carbon steel, stainless steel or alloy steel.

Parallel Machine Keys

Parallel keys are the most widely used. They have a square or rectangular cross-section. Parallel keys include Square Keys, Rectangular Keys. The shaft is usually key slotted for the full length for the shaft or slotted from the end of the shaft and along the length of the shaft for a distance greater than the length of the key to be used. Parallel keys can be installed by lining up the keyslots in the shaft and the component and then pressing the parallel key between the slots. There are three shapes of parallel keys depending on the ends of the keys. The end of a key can be either square or radius or round. The type of ends are referred to as “Forms”. Form A refers to a round end and Form B refers to a square end. For a Form A key, both ends are round, sometimes called the double round key. Form B key has both ends square. Form AB is a key with one end round and one end square, sometimes called the single round key.

Woodruff Keys

A woodruff key is a half moon shaped key that is inserted into a curved slot in the shaft. Woodruff keys are machined metal fasteners used to transfer torque from a shaft to gears where tight tolerances and functionality are vital. They are precisely a fail-safe device to ensure that the key breaks before the gears do, cutting replacement costs down significantly. Woodruff keys are used in a variety of applications including, lawn and garden equipment, automobiles, trucks, pumps, electric motors, agricultural equipment and other heavy equipment. They are used more often than machine keys in automated assemblies, such as automotive, because they are easier to feed and maintain tight tolerances. No matter the application, the woodruff key’s job is the same, to transfer the torque by locking the gears into the crank shaft.

Machine Key Standards

Metric Woodruff Key Chart Sizes

There are two sets of standards in the world – one for the imperial (inch) and another for metric (mm). DIN 6885 and JIS B 1301 deals with metric keys and ANSI B17.1 and BS 46 deals with imperial machine keys. These standards define the material, dimensions, tolerance and finish of the keys. There is a great similarity between DIN 6885 and JIS B 1301-1996. DIN 6885 is more popular in Europe and JIS in Asia.

- ANSI B17.1 By American National Standard Institute

- DIN6885 from German

- JIS B 1301-1996 from Japan

- BS 46 from England

- GB 1567-2003 from China

Let Machine Keystock ship your machine keystock to you fast as the lowest price!

Need Small Quantities Fast?

This is our retail website for small quantities of the most popular machine keys shipped within 48 hours.